The distributed batching system is computer technology. Control technology. Communication technology and graphic display technology combined product, its control function is perfect, display, operation, data processing is convenient, installation, maintenance is simple, the system is easy to expand. In the structure to solve the computer centralized control system of a "risk concentration" problem, to achieve "management centralized risk dispersion", so that any controller, even the main computer failure when the total impact is reduced to a minimum.

1. Product details

The distributed batching system is computer technology. Control technology. Communication technology and graphic display technology combined product, its control function is perfect, display, operation, data processing is convenient, installation, maintenance is simple, the system is easy to expand. In the structure to solve the computer centralized control system of a "risk concentration" problem, to achieve "management centralized risk dispersion", so that any controller, even the main computer failure when the total impact is reduced to a minimum. Since the control action is carried out at the lowest level, only the part concerned with the faulty controller in a single field control unit is affected, and the affected function is limited to this area, which greatly enhances the reliability of the batching system and meets the requirements for use in the continuous production process.

Two, the main characteristics of the system

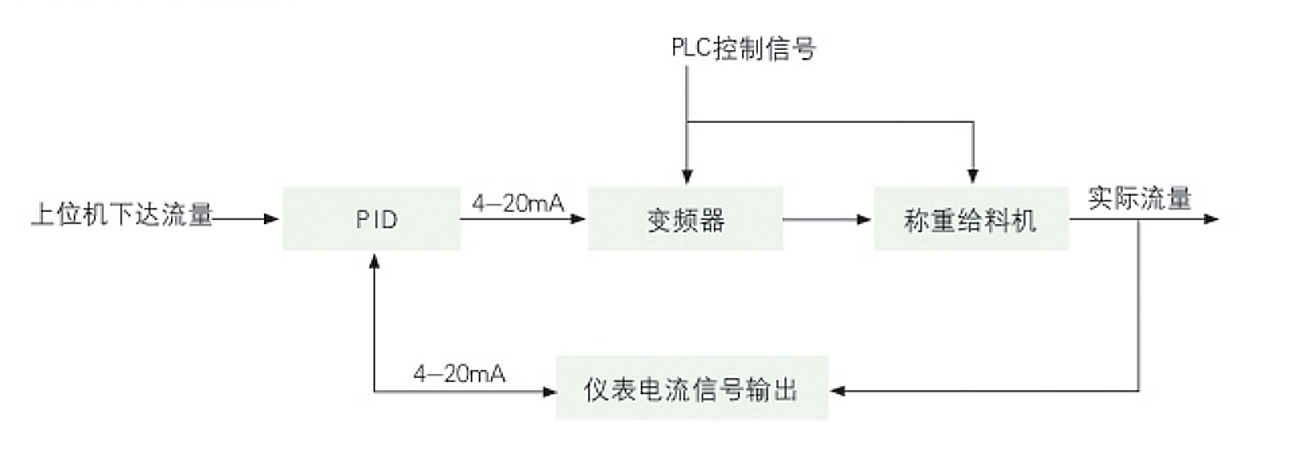

According to the production process requirements, through the optimal PID calculation, automatic control of the output of the feeder, adjust the material flow, so that the batching system to achieve the best ratio, to meet the batching accuracy;

According to production requirements, the program can set the best switching time sequence, better solve the problem of material head, material tail and residual material;

The system has automatic/manual uninterrupted switching function;

The batching scale has the functions of automatic zero adjustment, hanging code calibration, chain code calibration, physical verification, data power failure maintenance, etc.

The digital regulator has optional P, PI, PD, PID and other control algorithms, and has the function of keeping system parameters off power.

Software and hardware interlock interlocking function, good security, high reliability;

It can automatically detect the height of the material level and dynamically simulate the quantity of the material in the bin. It has the alarm function of the high and low limit of the quantity of the material in the bin.

Automatic detection of disc feeder or other upper conveyor plugging state, alarm, intelligent supply of cutting accident signal, to meet the batching process requirements;

Through the computer switching quantity data acquisition and industrial network communication technology, the whole batching process can be simulated dynamically in real time, the dynamic picture is realistic and the interface is friendly.

The system can dynamically add production formula and switch timing, can easily modify, query, print formula and switch timing;

Dynamic display of real-time batching curve, batching bar chart and historical curve;

The system can query and print the daily report of the shift, daily report of the month, real-time random and regular print the daily report of the shift;

Support network data sharing, support 32-bit ODBC open data, Internet machine authorized by the network administrator can query the relevant data support WINDOWSNT, NOVELL LAN, also can dial up the Internet through the modem;

The system software supports WINDOWS multi-process and multi-threading mechanism, the code optimization is excellent, the execution speed is fast, and the system resources are less occupied.

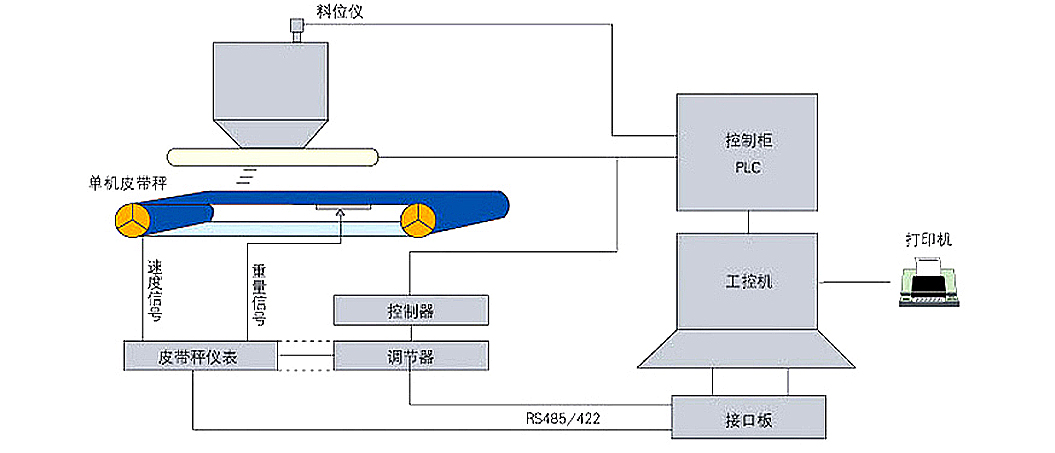

The single belt scale has the function of automatic correction, the tension adjustment device and the waist drum can adjust the conveyor belt to the best position and the best relaxation;

The weighing bridge in the single belt scale is installed on the longitudinal beam of the conveyor, which has the characteristics of strong rigidity, anti-deflection load and resistance to horizontal component force.

3.the working principle

The disc feeder or other upper conveyor transmits the material to the single belt scale. The weight signal and speed signal of the single belt scale enter the integrator and are processed and displayed inside the integrator. At the same time, the 4-20mA current signal proportional to the flow rate is output to the intelligent regulator. According to the PID parameters set by the user and the ideal control value, the regulator outputs 4-20mA current to the motor controller and adjusts the speed of the feeder, so as to achieve the purpose of controlling the feeding amount.

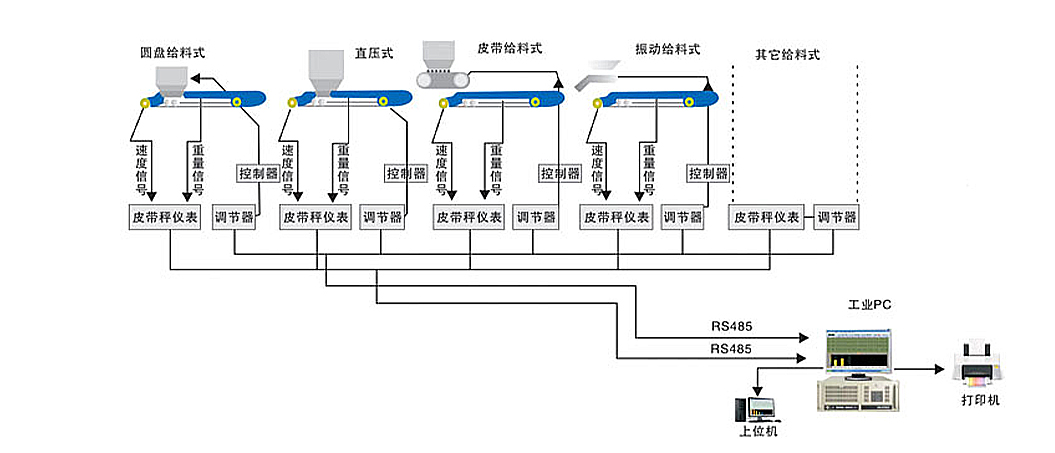

4. system composition

Batching system mainly consists of on-site production equipment, single belt scale (including conveyor system, belt scale body, weighing instrument. Weighing sensor. Speed sensor equipment). Regulator, frequency conversion controller, PLC, electrical control cabinet, upper computer, system software and material level detection device.

5. Distributed batching system hardware distribution diagram

5.Product parameters

Belt scale measurement error: ≤ 0.5% or ≤ 1.0%

Batching system accuracy: ≤1.0% or 2.0%

Ambient temperature: -20C to 70C

System batching capacity range: 0~800t /h

Material level measurement accuracy: soil 0.5% or 1.0%

Power supply: 380/220VAC, 50Hz

Current output: 0~20mA or 4~20mA proportional to the single belt scale flow

Communication network: RS-485/232